80 Series Cable Chain

80 Series Cable Chains--- Non-Closed & Closed

Introduction of guide chains:

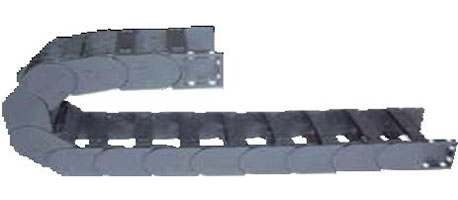

Material:Enhanced polyamide with high tension and pull-out strength, excellent flexibility, steady-going capacity in high or low temperature. lt can be used outdoors.

Resistant against: oil, salt, light acid, soft lye.

Max velocity and max accelertion respectively: 5m/s and 5m/s (specific information may be decided by operation conditions); Operation life:

Under the condition of normal overhead use, it can reach 5 million times for reciprocating motion (detailed life in accordance with operation conditions).

| Tensile Strength | 180N/mm | Volume Resistance | 1010~1015Ω |

| Impact Strength | 50KJ/m | Water Absorption(23℃) | 4% |

| Temperature Range | -40℃~130℃ | Friction Coefficient | 0.3 |

| Surface Resistance | 1010~1012Ω | Flame-retardant | HB (UL94) |

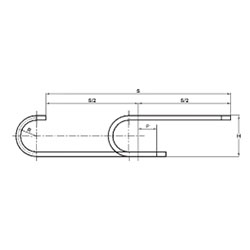

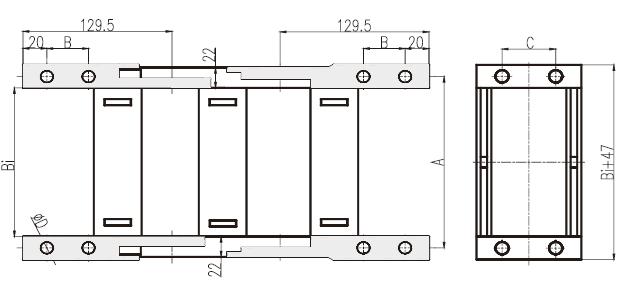

Mounting Bracket

L=S/2+πR+K

Length of chains

: L=S/2+πR+K(spare space)

K=P+(2~3)T

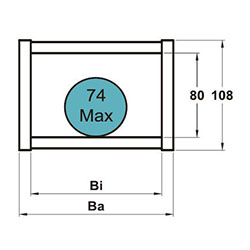

Specification

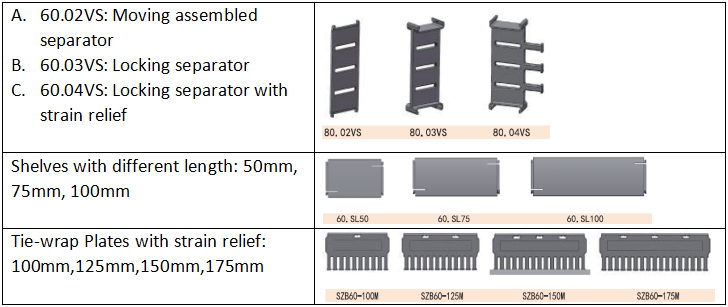

Separators can be selected:80.01VS can be installed both in non-closed & closed chains

The detailed value of R must be chosen from the dimensions

|

Type |

Inner Width |

Outer width |

Type |

(mm) |

(mm) |

(mm) |

(mm) |

|

Bi(mm) |

Ba(mm) |

fixed connector |

|||||

|

80.100.R |

100 |

144 |

80.100.12PZ |

125 |

35 |

66 |

11 |

|

80.125.R |

125 |

169 |

80.125.12PZ |

150 |

35 |

66 |

11 |

|

80.150.R |

150 |

194 |

80.150.12PZ |

175 |

35 |

66 |

11 |

|

80.175.R |

175 |

219 |

80.175.12PZ |

200 |

35 |

66 |

11 |

|

80.200.R |

200 |

244 |

80.200.12PZ |

225 |

35 |

66 |

11 |

|

80.250.R |

250 |

294 |

80.250.12PZ |

275 |

35 |

66 |

11 |

|

80.300.R |

300 |

344 |

80.300.12PZ |

325 |

35 |

66 |

11 |

|

80.350.R |

350 |

394 |

80.350.12PZ |

375 |

35 |

66 |

11 |

|

80.400.R |

400 |

444 |

80.400.12PZ |

425 |

35 |

66 |

11 |

|

80C.100.R |

100 |

144 |

80C.100.12PZ |

125 |

35 |

66 |

11 |

|

80C.125.R |

125 |

169 |

80C.125.12PZ |

150 |

35 |

66 |

11 |

|

80C.150.R |

150 |

194 |

80C.150.12PZ |

175 |

35 |

66 |

11 |

|

80C.175.R |

175 |

219 |

80C.175.12PZ |

200 |

35 |

66 |

11 |

|

80C.200.R |

200 |

244 |

80C.200.12PZ |

225 |

35 |

66 |

11 |

|

80C.250.R |

250 |

294 |

80C.250.12PZ |

275 |

35 |

66 |

11 |

|

80C.300.R |

300 |

344 |

80C.300.12PZ |

325 |

35 |

66 |

11 |

|

80C.350.R |

350 |

394 |

80C.350.12PZ |

375 |

35 |

66 |

11 |

|

80C.400.R |

400 |

444 |

80C.400.12PZ |

425 |

35 |

66 |

11 |

Note: Type No. “xxC” for closed type, whole “xx” for non-closed type

Accessories—Interior Separation for Non-closed Chains

Advantages of Cable Chains:

Guiding the cables for moving

Protecting the cables when moving up and down

Applied in the condition of light load, medium or short distance, slow speed, etc.

Application of guide chains

Applied to use in reciprocating motion so as to have traction and protection effects on built-in cables, inner oil tubes, gas tubes. water tubes, etc;

Each segmental part of the engineering plastic cable chain can be opened for easy installation and maintaining; While working, the engineering plastic chain is in low noise, anti-abrasion, high speed movement;

Widely applied to numerically controlled machine tools, electronic devices, dimension stone mechanism, glass mechanism, door-window mechanism, plastic jetting-moulding machine, manipulator, weight handling equipment, auto warehouse, etc.