Wire Braiding

Introduction of Polyamide Tubing

HG-CU

| Material | Tinned copper wire |

| Temperature Range | Min-75℃,Max150℃ |

| Structure | Braiding consisting of round braided wires with double crossed looping at the different braiding angles |

| Properties | Axially pushed together, in a certain proportion, depending upon the construction of the braiding; easy pulling in of cables; the braiding become protection from hot swarfs |

| Applications | Highly flexible hollow metal braided tube, can be used as shielding and protective braided tube, especially suitable for shielding occasions |

Tech Specification

| Type | Number of strands×Number of | Range of Application | Weight | Packet |

| roots×single line diameter | φmm | kg/m | (m/roll) | |

| HG-CU NW6 | 24×8×0.12 | 3.2-9.5 | 0.07 | 200 |

| HG-CU NW10 | 48×6×0.15 | 4.7-15.9 | 0.093 | 200 |

| HG-CU NW15 | 48×12×0.15 | 10-23 | 0.109 | 100 |

| HG-CU NW20 | 48×15×0.15 | 12-31.5 | 0.196 | 100 |

| HG-CU NW25 | 48×20×0.15 | 15-34 | 0.336 | 100 |

| HG-CU NW35 | 48×28×0.15 | 19-38 | 0.37 | 50 |

Advantages of Wire Braiding

1. Easy to pull in the cable.

2. Heat-resistant metal shavings

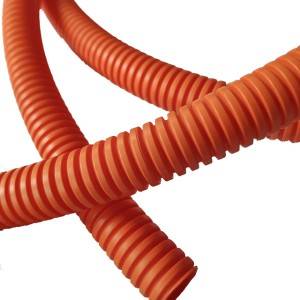

Pictures of Tubing

Application Wire Tubing

Highly flexible hollow metal braided tube, can be used as shielding and protective braided tube, especially suitable for shielding occasions.