Hot Sale for Cable Gland For Flexible Conduit - Explosion-proof Metal Cable Gland (Metric/PG/NPT/G thread) – Weyer

Hot Sale for Cable Gland For Flexible Conduit - Explosion-proof Metal Cable Gland (Metric/PG/NPT/G thread) – Weyer Detail:

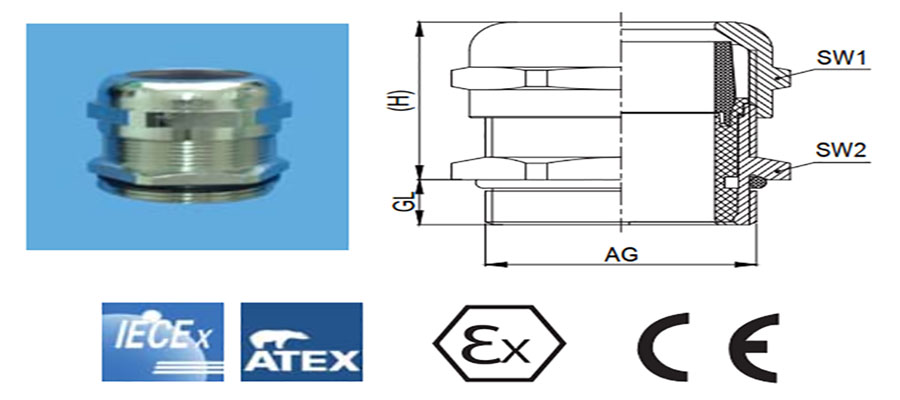

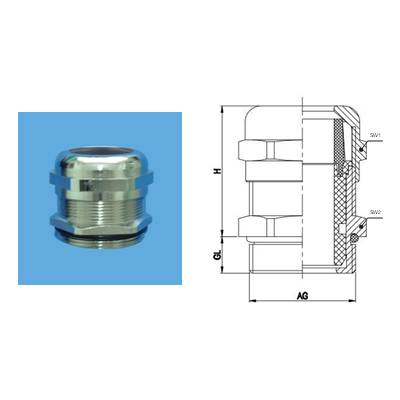

Explosion-proof Metal Cable Gland (Metric/PG/NPT/G thread)

Introduction

Cable glands are mainly used to clamp, fix, protect the cables from water and dust. They are widely applied to such fields as control boards, apparatuses, lights, mechanical equipment, train, motors, projects etc.We can provide you with metal cable glands made of nickel-plated brass (Order No.: HSM-EX) and stainless steel (Order No.: HSMS-EX).

| Material: | Body: nickel-plated brass; seal: polyamide; sealing: modified rubber |

| Temperature Range: | Min -40℃, Max 100℃, Short-term 120℃ |

| Protection degree: | IP68(IEC60529) with suitable O-ring within specified clamping range |

| Properties: | Resistance to vibration and impact, in accordance with IEC-60077-1999. |

| Applications: | Machine building, electric equipment, electric control cupboard |

| Certifications: | CE, RoHS, Exe II Gb, IECEx, ATEX. |

Specification

(Please contact us for more information if you need other sizes not included in the following list.)

|

Explosion-proof Nickel-plated brass cable gland (Metric thread) |

|||||||

|

Article no. |

Thread |

Hole size |

AG |

GL |

H |

SW1/SW2 |

Packet |

|

Dimension |

mm |

mm |

mm |

mm |

mm |

units |

|

|

HSM-EX-M12 |

M12×1.5 |

3~6.5 |

12 |

6 |

19 |

14/14 |

75 |

|

HSM-EX-M16-H |

M16×1.5 |

3~6.5 |

16 |

7 |

20 |

14/18 |

75 |

|

HSM-EX-M16 |

M16×1.5 |

4~8 |

16 |

7 |

21 |

17/18 |

75 |

|

HSM-EX-M16-D |

M16×1.5 |

5~10 |

16 |

7 |

22.5 |

20/20 |

32 |

|

HSM-EX-M18 |

M18×1.5 |

5~10 |

18 |

7 |

22.5 |

20/20 |

50 |

|

HSM-EX-M20-H |

M20×1.5 |

5~10 |

20 |

7 |

22.5 |

20/22 |

32 |

|

HSM-EX-M20 |

M20×1.5 |

6~12 |

20 |

7 |

23.5 |

22/22 |

32 |

|

HSM-EX-M20-D |

M20×1.5 |

8~14 |

20 |

7 |

23 |

24/24 |

32 |

|

HSM-EX-M22 |

M22×1.5 |

8~14 |

22 |

7 |

23 |

24/24 |

32 |

|

HSM-EX-M24-H |

M24×1.5 |

6~12 |

24 |

7 |

23.5 |

24/27 |

18 |

|

HSM-EX-M24 |

M24×1.5 |

8~14 |

24 |

7 |

23 |

24/27 |

18 |

|

HSM-EX-M25-H |

M25×1.5 |

8~14 |

25 |

7 |

23 |

24/28 |

18 |

|

HSM-EX-M25 |

M25×1.5 |

10~16 |

25 |

7 |

24.5 |

28/28 |

18 |

|

HSM-EX-M25-D |

M25×1.5 |

13~18 |

25 |

7 |

26 |

30/30 |

18 |

|

HSM-EX-M27-H |

M27×2.0 |

10~16 |

27 |

8 |

24.5 |

28/30 |

18 |

|

HSM-EX-M27 |

M27×2.0 |

13~18 |

27 |

8 |

26 |

30/30 |

18 |

|

HSM-EX-M30-H |

M30×2.0 |

10~16 |

30 |

8 |

24.5 |

28/34 |

18 |

|

HSM-EX-M30 |

M30×2.0 |

13~18 |

30 |

8 |

26 |

30/34 |

18 |

|

HSM-EX-M32-H |

M32×1.5 |

13~18 |

32 |

8 |

26 |

30/36 |

8 |

|

HSM-EX-M32 |

M32×1.5 |

15~22 |

32 |

8 |

28 |

36/36 |

18 |

|

HSM-EX-M32-D |

M32×1.5 |

18~25 |

32 |

8 |

33 |

40/38 |

8 |

|

HSM-EX-M33 |

M33×2.0 |

18~25 |

33 |

8 |

33 |

40/38 |

8 |

|

HSM-EX-M36-H |

M36×2.0 |

15~22 |

36 |

8 |

28 |

36/40 |

8 |

|

HSM-EX-M36 |

M36×2.0 |

18~25 |

36 |

8 |

33 |

40/40 |

8 |

|

HSM-EX-M40-H |

M40×1.5 |

18~25 |

40 |

9 |

33.5 |

40/45 |

8 |

|

HSM-EX-M40 |

M40×1.5 |

22~30 |

40 |

9 |

35.5 |

45/45 |

8 |

|

HSM-EX-M40-D |

M40×1.5 |

22~32 |

40 |

9 |

38.5 |

50/50 |

4 |

|

HSM-EX-M42 |

M42×2.0 |

22~32 |

42 |

9 |

38.5 |

50/50 |

4 |

|

HSM-EX-M48 |

M48×2.0 |

22~32 |

48 |

9 |

38.5 |

50/52 |

4 |

|

HSM-EX-M50 |

M50×1.5 |

30~38 |

50 |

9 |

40 |

58/55 |

4 |

|

HSM-EX-M56 |

M56×2.0 |

30~38 |

56 |

9 |

40 |

58/60 |

2 |

|

HSM-EX-M60 |

M60×2.0 |

37~44 |

60 |

10 |

41 |

65/65 |

2 |

|

HSM-EX-M63 |

M63×1.5 |

37~44 |

63 |

10 |

41 |

65/70 |

2 |

|

HSM-EX-M63-D |

M63×1.5 |

42~53 |

63 |

10 |

44.5 |

75/75 |

2 |

|

HSM-EX-M64 |

M64×2.0 |

37~44 |

64 |

10 |

41 |

65/70 |

2 |

|

Explosion-proof Nickel-plated brass cable gland (PG thread) |

|||||||

|

Article no. |

Thread |

Hole size |

AG |

GL |

H |

SW1/SW2 |

Packet |

|

Dimension |

mm |

mm |

mm |

mm |

mm |

units |

|

|

HSM-EX-P07 |

PG7 |

3~6.5 |

12.5 |

6 |

19 |

14/14 |

75 |

|

HSM-EX-P09-H |

PG9 |

3~6.5 |

15.2 |

7 |

20 |

14/17 |

75 |

|

HSM-EX-P09 |

PG9 |

4~8 |

15.2 |

7 |

21 |

17/17 |

75 |

|

HSM-EX-P11 |

PG11 |

5~10 |

18.6 |

7 |

22.5 |

20/22 |

75 |

|

HSM-EX-P13.5-H |

PG13.5 |

5~10 |

20.4 |

7 |

22.5 |

22/22 |

32 |

|

HSM-EX-P13.5 |

PG13.5 |

6~12 |

20.4 |

7 |

23.5 |

22/22 |

32 |

|

HSM-EX-P16-H |

PG16 |

6~12 |

22.5 |

7 |

23.5 |

22/24 |

32 |

|

HSM-EX-P16 |

PG16 |

8~14 |

22.5 |

7 |

23 |

24/24 |

32 |

|

HSM-EX-P21-H |

PG21 |

10~16 |

28.3 |

7 |

24.5 |

28/30 |

18 |

|

HSM-EX-P21 |

PG21 |

13~18 |

28.3 |

7 |

26 |

30/30 |

18 |

|

HSM-EX-P29-H |

PG29 |

15~22 |

37 |

8 |

28 |

36/40 |

8 |

|

HSM-EX-P29 |

PG29 |

18~25 |

37 |

8 |

33 |

40/40 |

8 |

|

HSM-EX-P36 |

PG36 |

22~32 |

47 |

9 |

38.5 |

50/50 |

4 |

|

HSM-EX-P42 |

PG42 |

30~38 |

54 |

9 |

40 |

58/58 |

2 |

|

HSM-EX-P48 |

PG48 |

37~44 |

59.3 |

10 |

41 |

65/65 |

2 |

|

Explosion-proof Nickel-plated brass cable gland (PG thread: lengthened thread) |

|||||||

|

Article no. |

Thread |

Hole size |

AG |

GL |

H |

SW1/SW2 |

Packet |

|

Dimension |

mm |

mm |

mm |

mm |

mm |

units |

|

|

HSM-EX-P07-L |

PG7 |

3~6.5 |

12.5 |

10 |

19 |

14/14 |

50 |

|

HSM-EX-P09-HL |

PG9 |

3~6.5 |

15.2 |

10 |

20 |

14/17 |

50 |

|

HSM-EX-P09-L |

PG9 |

4~8 |

15.2 |

10 |

21 |

17/17 |

50 |

|

HSM-EX-P11-L |

PG11 |

5~10 |

18.6 |

10 |

22.5 |

20/20 |

50 |

|

HSM-EX-P13.5-HL |

PG13.5 |

5~10 |

20.4 |

10 |

22.5 |

20/22 |

32 |

|

HSM-EX-P13.5-L |

PG13.5 |

6~12 |

20.4 |

10 |

23.5 |

22/22 |

32 |

|

HSM-EX-P16-HL |

PG16 |

6~12 |

22.5 |

10 |

23.5 |

22/24 |

32 |

|

HSM-EX-P16-L |

PG16 |

8~14 |

22.5 |

10 |

23 |

24/24 |

32 |

|

HSM-EX-P21-HL |

PG21 |

10~16 |

28.3 |

12 |

24.5 |

28/30 |

18 |

|

HSM-EX-P21-L |

PG21 |

13~18 |

28.3 |

12 |

26 |

30/30 |

18 |

|

HSM-EX-P29-HL |

PG29 |

15~22 |

37 |

12 |

28 |

36/40 |

8 |

|

HSM-EX-P29-L |

PG29 |

18~25 |

37 |

12 |

33 |

40/40 |

8 |

|

HSM-EX-P36-L |

PG36 |

22~32 |

47 |

15 |

38.5 |

50/50 |

2 |

|

HSM-EX-P42-L |

PG42 |

30~38 |

54 |

15 |

40 |

58/58 |

2 |

|

HSM-EX-P48-L |

PG48 |

37~44 |

59.3 |

15 |

41 |

65/65 |

2 |

|

Explosion-proof Nickel-plated brass cable gland (G thread) |

|||||||

|

Article no. |

Thread |

Hole size |

AG |

GL |

H |

SW1/SW2 |

Packet |

|

Dimension |

mm |

mm |

mm |

mm |

mm |

units |

|

|

HSM-EX-G3/8 |

G3/8″ |

4~8 |

16.66 |

8 |

21 |

17/20 |

32 |

|

HSM-EX-G1/2-H |

G1/2″ |

5~10 |

20.99 |

8 |

22.5 |

20/24 |

32 |

|

HSM-EX-G1/2 |

G1/2″ |

6~12 |

20.99 |

8 |

23.5 |

22/24 |

32 |

|

HSM-EX-G1/2-D |

G1/2″ |

8~14 |

20.99 |

8 |

23.5 |

24/24 |

32 |

|

HSM-EX-G3/4-TH |

G3/4″ |

6~12 |

26.44 |

8 |

23.5 |

22/30 |

18 |

|

HSM-EX-G3/4-H |

G3/4″ |

8~14 |

26.44 |

8 |

23.5 |

24/30 |

18 |

|

HSM-EX-G3/4 |

G3/4″ |

13~18 |

26.44 |

8 |

26 |

30/30 |

18 |

|

HSM-EX-G1 |

G1″ |

18~25 |

33.24 |

9 |

33 |

40/40 |

8 |

|

HSM-EX-G1 1/4 |

G1 1/4″ |

22~32 |

41.91 |

10 |

38.5 |

50/50 |

4 |

|

HSM-EX-G1 1/2 |

G1 1/2″ |

30~38 |

47.8 |

10 |

40 |

58/55 |

2 |

|

HSM-EX-G2 |

G2″ |

37~44 |

59.61 |

11 |

41 |

65/65 |

2 |

|

Explosion-proof Nickel-plated brass cable gland (NPT thread) |

|||||||

|

Article no. |

Thread |

Hole size |

AG |

GL |

H |

SW1/SW2 |

Packet |

|

Dimension |

mm |

mm |

mm |

mm |

mm |

units |

|

|

HSM-EX-N3/8 |

NPT3/8 |

4~8 |

16.65 |

16 |

21 |

17/20 |

32 |

|

HSM-EX-N1/2-H |

NPT1/2″ |

5~10 |

21.85 |

20 |

22.5 |

20/23 |

32 |

|

HSM-EX-N1/2 |

NPT1/2″ |

6~12 |

21.85 |

20 |

23.5 |

22/23 |

32 |

|

HSM-EX-N1/2-D |

NPT1/2″ |

8~14 |

21.85 |

20 |

23.5 |

24/24 |

32 |

|

HSM-EX-N3/4-TH |

NPT3/4″ |

6~12 |

26.3 |

21 |

23.5 |

22/30 |

18 |

|

HSM-EX-N3/4-H |

NPT3/4″ |

8~14 |

26.3 |

21 |

23 |

24/30 |

18 |

|

HSM-EX-N3/4 |

NPT3/4″ |

13~18 |

26.3 |

21 |

26 |

30/30 |

18 |

|

HSM-EX-N1 |

NPT1″ |

18~25 |

33.15 |

26 |

33 |

40/40 |

8 |

|

HSM-EX-N1 1/4 |

NPT1 1/4″ |

22~32 |

41.85 |

26 |

38.5 |

50/50 |

4 |

|

HSM-EX-N1 1/2 |

NPT1 1/2″ |

30~38 |

47.75 |

27 |

40 |

58/55 |

2 |

|

HSM-EX-N2 |

NPT2″ |

37~44 |

59.55 |

27 |

41 |

65/65 |

2 |

Product detail pictures:

Related Product Guide:

We support our prospective buyers with ideal top quality merchandise and superior level provider. Becoming the specialist manufacturer in this sector, we have now attained abundant practical expertise in producing and managing for Hot Sale for Cable Gland For Flexible Conduit - Explosion-proof Metal Cable Gland (Metric/PG/NPT/G thread) – Weyer, The product will supply to all over the world, such as: Bolivia, Accra, New Zealand, With a fully integrated operation system, our company has won a good fame for our high quality products, reasonable prices and good services. Meanwhile, we have established a strict quality management system conducted in material incoming, processing and delivery. Abiding by the principle of "Credit first and customer supremacy", we sincerely welcome clients from home and abroad to cooperate with us and advance together to create a brilliant future.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.