Factory Supply Openable T-Distributor for corrugated conduit - Explosion-proof Metal Cable Gland (Metric/PG/NPT/G thread) – Weyer

Factory Supply Openable T-Distributor for corrugated conduit - Explosion-proof Metal Cable Gland (Metric/PG/NPT/G thread) – Weyer Detail:

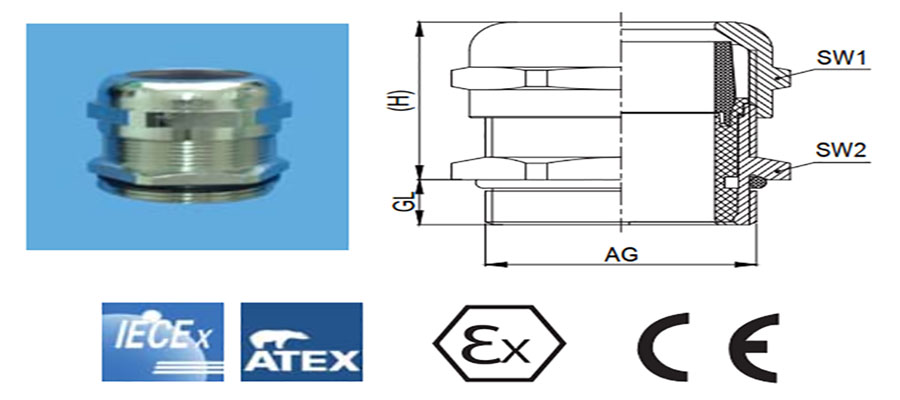

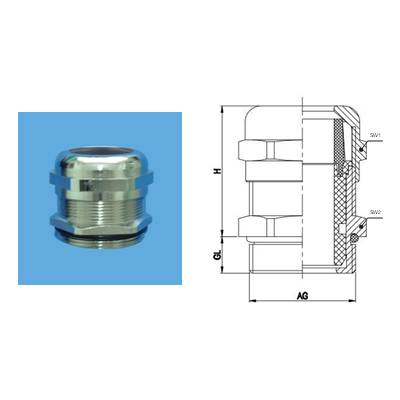

Explosion-proof Metal Cable Gland (Metric/PG/NPT/G thread)

Introduction

Cable glands are mainly used to clamp, fix, protect the cables from water and dust. They are widely applied to such fields as control boards, apparatuses, lights, mechanical equipment, train, motors, projects etc.We can provide you with metal cable glands made of nickel-plated brass (Order No.: HSM-EX) and stainless steel (Order No.: HSMS-EX).

| Material: | Body: nickel-plated brass; seal: polyamide; sealing: modified rubber |

| Temperature Range: | Min -40℃, Max 100℃, Short-term 120℃ |

| Protection degree: | IP68(IEC60529) with suitable O-ring within specified clamping range |

| Properties: | Resistance to vibration and impact, in accordance with IEC-60077-1999. |

| Applications: | Machine building, electric equipment, electric control cupboard |

| Certifications: | CE, RoHS, Exe II Gb, IECEx, ATEX. |

Specification

(Please contact us for more information if you need other sizes not included in the following list.)

|

Explosion-proof Nickel-plated brass cable gland (Metric thread) |

|||||||

|

Article no. |

Thread |

Hole size |

AG |

GL |

H |

SW1/SW2 |

Packet |

|

Dimension |

mm |

mm |

mm |

mm |

mm |

units |

|

|

HSM-EX-M12 |

M12×1.5 |

3~6.5 |

12 |

6 |

19 |

14/14 |

75 |

|

HSM-EX-M16-H |

M16×1.5 |

3~6.5 |

16 |

7 |

20 |

14/18 |

75 |

|

HSM-EX-M16 |

M16×1.5 |

4~8 |

16 |

7 |

21 |

17/18 |

75 |

|

HSM-EX-M16-D |

M16×1.5 |

5~10 |

16 |

7 |

22.5 |

20/20 |

32 |

|

HSM-EX-M18 |

M18×1.5 |

5~10 |

18 |

7 |

22.5 |

20/20 |

50 |

|

HSM-EX-M20-H |

M20×1.5 |

5~10 |

20 |

7 |

22.5 |

20/22 |

32 |

|

HSM-EX-M20 |

M20×1.5 |

6~12 |

20 |

7 |

23.5 |

22/22 |

32 |

|

HSM-EX-M20-D |

M20×1.5 |

8~14 |

20 |

7 |

23 |

24/24 |

32 |

|

HSM-EX-M22 |

M22×1.5 |

8~14 |

22 |

7 |

23 |

24/24 |

32 |

|

HSM-EX-M24-H |

M24×1.5 |

6~12 |

24 |

7 |

23.5 |

24/27 |

18 |

|

HSM-EX-M24 |

M24×1.5 |

8~14 |

24 |

7 |

23 |

24/27 |

18 |

|

HSM-EX-M25-H |

M25×1.5 |

8~14 |

25 |

7 |

23 |

24/28 |

18 |

|

HSM-EX-M25 |

M25×1.5 |

10~16 |

25 |

7 |

24.5 |

28/28 |

18 |

|

HSM-EX-M25-D |

M25×1.5 |

13~18 |

25 |

7 |

26 |

30/30 |

18 |

|

HSM-EX-M27-H |

M27×2.0 |

10~16 |

27 |

8 |

24.5 |

28/30 |

18 |

|

HSM-EX-M27 |

M27×2.0 |

13~18 |

27 |

8 |

26 |

30/30 |

18 |

|

HSM-EX-M30-H |

M30×2.0 |

10~16 |

30 |

8 |

24.5 |

28/34 |

18 |

|

HSM-EX-M30 |

M30×2.0 |

13~18 |

30 |

8 |

26 |

30/34 |

18 |

|

HSM-EX-M32-H |

M32×1.5 |

13~18 |

32 |

8 |

26 |

30/36 |

8 |

|

HSM-EX-M32 |

M32×1.5 |

15~22 |

32 |

8 |

28 |

36/36 |

18 |

|

HSM-EX-M32-D |

M32×1.5 |

18~25 |

32 |

8 |

33 |

40/38 |

8 |

|

HSM-EX-M33 |

M33×2.0 |

18~25 |

33 |

8 |

33 |

40/38 |

8 |

|

HSM-EX-M36-H |

M36×2.0 |

15~22 |

36 |

8 |

28 |

36/40 |

8 |

|

HSM-EX-M36 |

M36×2.0 |

18~25 |

36 |

8 |

33 |

40/40 |

8 |

|

HSM-EX-M40-H |

M40×1.5 |

18~25 |

40 |

9 |

33.5 |

40/45 |

8 |

|

HSM-EX-M40 |

M40×1.5 |

22~30 |

40 |

9 |

35.5 |

45/45 |

8 |

|

HSM-EX-M40-D |

M40×1.5 |

22~32 |

40 |

9 |

38.5 |

50/50 |

4 |

|

HSM-EX-M42 |

M42×2.0 |

22~32 |

42 |

9 |

38.5 |

50/50 |

4 |

|

HSM-EX-M48 |

M48×2.0 |

22~32 |

48 |

9 |

38.5 |

50/52 |

4 |

|

HSM-EX-M50 |

M50×1.5 |

30~38 |

50 |

9 |

40 |

58/55 |

4 |

|

HSM-EX-M56 |

M56×2.0 |

30~38 |

56 |

9 |

40 |

58/60 |

2 |

|

HSM-EX-M60 |

M60×2.0 |

37~44 |

60 |

10 |

41 |

65/65 |

2 |

|

HSM-EX-M63 |

M63×1.5 |

37~44 |

63 |

10 |

41 |

65/70 |

2 |

|

HSM-EX-M63-D |

M63×1.5 |

42~53 |

63 |

10 |

44.5 |

75/75 |

2 |

|

HSM-EX-M64 |

M64×2.0 |

37~44 |

64 |

10 |

41 |

65/70 |

2 |

|

Explosion-proof Nickel-plated brass cable gland (PG thread) |

|||||||

|

Article no. |

Thread |

Hole size |

AG |

GL |

H |

SW1/SW2 |

Packet |

|

Dimension |

mm |

mm |

mm |

mm |

mm |

units |

|

|

HSM-EX-P07 |

PG7 |

3~6.5 |

12.5 |

6 |

19 |

14/14 |

75 |

|

HSM-EX-P09-H |

PG9 |

3~6.5 |

15.2 |

7 |

20 |

14/17 |

75 |

|

HSM-EX-P09 |

PG9 |

4~8 |

15.2 |

7 |

21 |

17/17 |

75 |

|

HSM-EX-P11 |

PG11 |

5~10 |

18.6 |

7 |

22.5 |

20/22 |

75 |

|

HSM-EX-P13.5-H |

PG13.5 |

5~10 |

20.4 |

7 |

22.5 |

22/22 |

32 |

|

HSM-EX-P13.5 |

PG13.5 |

6~12 |

20.4 |

7 |

23.5 |

22/22 |

32 |

|

HSM-EX-P16-H |

PG16 |

6~12 |

22.5 |

7 |

23.5 |

22/24 |

32 |

|

HSM-EX-P16 |

PG16 |

8~14 |

22.5 |

7 |

23 |

24/24 |

32 |

|

HSM-EX-P21-H |

PG21 |

10~16 |

28.3 |

7 |

24.5 |

28/30 |

18 |

|

HSM-EX-P21 |

PG21 |

13~18 |

28.3 |

7 |

26 |

30/30 |

18 |

|

HSM-EX-P29-H |

PG29 |

15~22 |

37 |

8 |

28 |

36/40 |

8 |

|

HSM-EX-P29 |

PG29 |

18~25 |

37 |

8 |

33 |

40/40 |

8 |

|

HSM-EX-P36 |

PG36 |

22~32 |

47 |

9 |

38.5 |

50/50 |

4 |

|

HSM-EX-P42 |

PG42 |

30~38 |

54 |

9 |

40 |

58/58 |

2 |

|

HSM-EX-P48 |

PG48 |

37~44 |

59.3 |

10 |

41 |

65/65 |

2 |

|

Explosion-proof Nickel-plated brass cable gland (PG thread: lengthened thread) |

|||||||

|

Article no. |

Thread |

Hole size |

AG |

GL |

H |

SW1/SW2 |

Packet |

|

Dimension |

mm |

mm |

mm |

mm |

mm |

units |

|

|

HSM-EX-P07-L |

PG7 |

3~6.5 |

12.5 |

10 |

19 |

14/14 |

50 |

|

HSM-EX-P09-HL |

PG9 |

3~6.5 |

15.2 |

10 |

20 |

14/17 |

50 |

|

HSM-EX-P09-L |

PG9 |

4~8 |

15.2 |

10 |

21 |

17/17 |

50 |

|

HSM-EX-P11-L |

PG11 |

5~10 |

18.6 |

10 |

22.5 |

20/20 |

50 |

|

HSM-EX-P13.5-HL |

PG13.5 |

5~10 |

20.4 |

10 |

22.5 |

20/22 |

32 |

|

HSM-EX-P13.5-L |

PG13.5 |

6~12 |

20.4 |

10 |

23.5 |

22/22 |

32 |

|

HSM-EX-P16-HL |

PG16 |

6~12 |

22.5 |

10 |

23.5 |

22/24 |

32 |

|

HSM-EX-P16-L |

PG16 |

8~14 |

22.5 |

10 |

23 |

24/24 |

32 |

|

HSM-EX-P21-HL |

PG21 |

10~16 |

28.3 |

12 |

24.5 |

28/30 |

18 |

|

HSM-EX-P21-L |

PG21 |

13~18 |

28.3 |

12 |

26 |

30/30 |

18 |

|

HSM-EX-P29-HL |

PG29 |

15~22 |

37 |

12 |

28 |

36/40 |

8 |

|

HSM-EX-P29-L |

PG29 |

18~25 |

37 |

12 |

33 |

40/40 |

8 |

|

HSM-EX-P36-L |

PG36 |

22~32 |

47 |

15 |

38.5 |

50/50 |

2 |

|

HSM-EX-P42-L |

PG42 |

30~38 |

54 |

15 |

40 |

58/58 |

2 |

|

HSM-EX-P48-L |

PG48 |

37~44 |

59.3 |

15 |

41 |

65/65 |

2 |

|

Explosion-proof Nickel-plated brass cable gland (G thread) |

|||||||

|

Article no. |

Thread |

Hole size |

AG |

GL |

H |

SW1/SW2 |

Packet |

|

Dimension |

mm |

mm |

mm |

mm |

mm |

units |

|

|

HSM-EX-G3/8 |

G3/8″ |

4~8 |

16.66 |

8 |

21 |

17/20 |

32 |

|

HSM-EX-G1/2-H |

G1/2″ |

5~10 |

20.99 |

8 |

22.5 |

20/24 |

32 |

|

HSM-EX-G1/2 |

G1/2″ |

6~12 |

20.99 |

8 |

23.5 |

22/24 |

32 |

|

HSM-EX-G1/2-D |

G1/2″ |

8~14 |

20.99 |

8 |

23.5 |

24/24 |

32 |

|

HSM-EX-G3/4-TH |

G3/4″ |

6~12 |

26.44 |

8 |

23.5 |

22/30 |

18 |

|

HSM-EX-G3/4-H |

G3/4″ |

8~14 |

26.44 |

8 |

23.5 |

24/30 |

18 |

|

HSM-EX-G3/4 |

G3/4″ |

13~18 |

26.44 |

8 |

26 |

30/30 |

18 |

|

HSM-EX-G1 |

G1″ |

18~25 |

33.24 |

9 |

33 |

40/40 |

8 |

|

HSM-EX-G1 1/4 |

G1 1/4″ |

22~32 |

41.91 |

10 |

38.5 |

50/50 |

4 |

|

HSM-EX-G1 1/2 |

G1 1/2″ |

30~38 |

47.8 |

10 |

40 |

58/55 |

2 |

|

HSM-EX-G2 |

G2″ |

37~44 |

59.61 |

11 |

41 |

65/65 |

2 |

|

Explosion-proof Nickel-plated brass cable gland (NPT thread) |

|||||||

|

Article no. |

Thread |

Hole size |

AG |

GL |

H |

SW1/SW2 |

Packet |

|

Dimension |

mm |

mm |

mm |

mm |

mm |

units |

|

|

HSM-EX-N3/8 |

NPT3/8 |

4~8 |

16.65 |

16 |

21 |

17/20 |

32 |

|

HSM-EX-N1/2-H |

NPT1/2″ |

5~10 |

21.85 |

20 |

22.5 |

20/23 |

32 |

|

HSM-EX-N1/2 |

NPT1/2″ |

6~12 |

21.85 |

20 |

23.5 |

22/23 |

32 |

|

HSM-EX-N1/2-D |

NPT1/2″ |

8~14 |

21.85 |

20 |

23.5 |

24/24 |

32 |

|

HSM-EX-N3/4-TH |

NPT3/4″ |

6~12 |

26.3 |

21 |

23.5 |

22/30 |

18 |

|

HSM-EX-N3/4-H |

NPT3/4″ |

8~14 |

26.3 |

21 |

23 |

24/30 |

18 |

|

HSM-EX-N3/4 |

NPT3/4″ |

13~18 |

26.3 |

21 |

26 |

30/30 |

18 |

|

HSM-EX-N1 |

NPT1″ |

18~25 |

33.15 |

26 |

33 |

40/40 |

8 |

|

HSM-EX-N1 1/4 |

NPT1 1/4″ |

22~32 |

41.85 |

26 |

38.5 |

50/50 |

4 |

|

HSM-EX-N1 1/2 |

NPT1 1/2″ |

30~38 |

47.75 |

27 |

40 |

58/55 |

2 |

|

HSM-EX-N2 |

NPT2″ |

37~44 |

59.55 |

27 |

41 |

65/65 |

2 |

Product detail pictures:

Related Product Guide:

We always continually offer you the most conscientious purchaser services, and the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for Factory Supply Openable T-Distributor for corrugated conduit - Explosion-proof Metal Cable Gland (Metric/PG/NPT/G thread) – Weyer, The product will supply to all over the world, such as: Canada, Moscow, Berlin, We have exported our products all over the world, especially the USA and European countries. Furthermore, all of our products are manufactured with advanced equipment and strict QC procedures to ensure high quality.If you are interested in any of our products, please don't hesitate to contact us. We will try our best to meet your needs.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!